High Compact Density LFP: Revolutionizing Battery Performance Through Advanced Cathode Materials

Release time:

2025-05-15

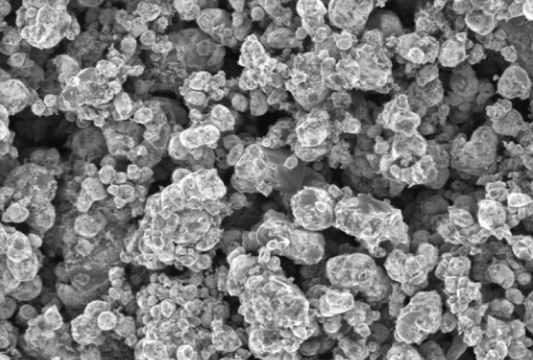

The rapid advancement of electric vehicles (EVs), renewable energy storage, and portable electronics has intensified the demand for high-performance lithium-ion batteries. Among various cathode materials, lithium iron phosphate (LFP) has emerged as a leading contender due to its inherent safety, long cycle life, and cost-effectiveness. However, traditional LFP cathodes face challenges such as lower energy density and slower charging rates compared to nickel-rich alternatives. To address these limitations, cutting-edge companies are now focusing on developing High Compact Density LFP, a next-generation material engineered to enhance battery longevity, safety, fast-charging capability, and energy efficiency through innovative research and material optimization.

At the core of this breakthrough is the refinement of LFP’s structural and electrochemical properties. By optimizing particle size distribution and improving crystallinity, researchers have significantly increased the material’s volumetric energy density. This allows batteries to store more energy in the same physical space, extending the range of EVs and the runtime of electronic devices. Additionally, advanced coating techniques and doping strategies are employed to enhance ionic and electronic conductivity. These modifications reduce internal resistance, enabling faster charging without compromising thermal stability—a critical advantage over conventional high-nickel cathodes prone to overheating.

Safety remains a paramount priority in battery development, and High Compact Density LFP excels in this regard. The robust olivine structure of LFP inherently resists thermal runaway, while the compact design further mitigates risks by minimizing electrode degradation during repeated charge-discharge cycles. Furthermore, the use of sustainable and low-cost raw materials aligns with global efforts to reduce reliance on scarce or ethically contentious resources like cobalt.

Efficiency is another key focus. By reducing inactive components and maximizing active material utilization, High Compact Density LFP batteries achieve higher energy efficiency, translating to less energy loss during operation. This not only improves performance but also lowers the total cost of ownership, making it an economically viable solution for large-scale applications.

In summary, High Compact Density LFP represents a transformative leap in battery technology. Through continuous research and material innovation, companies are unlocking the full potential of LFP cathodes, paving the way for safer, longer-lasting, and faster-charging energy storage solutions that meet the evolving needs of a electrified world.

Latest News

HOW CAN WE HELP ?

Get In Touch With Us!

Related Link: